Guide to Understanding Orbital Welding Machines

If you’re considering investing in an orbital welding machine, there are a number of factors to consider. Here’s a brief overview of the benefits of this equipment over manual welding. A quality orbital welding machine will last for decades and ensure the integrity of your welds. It also offers precision and speed that you can’t match with manual welding. However, you should also consider the cost of buying an orbital welding machine before you make the final decision.

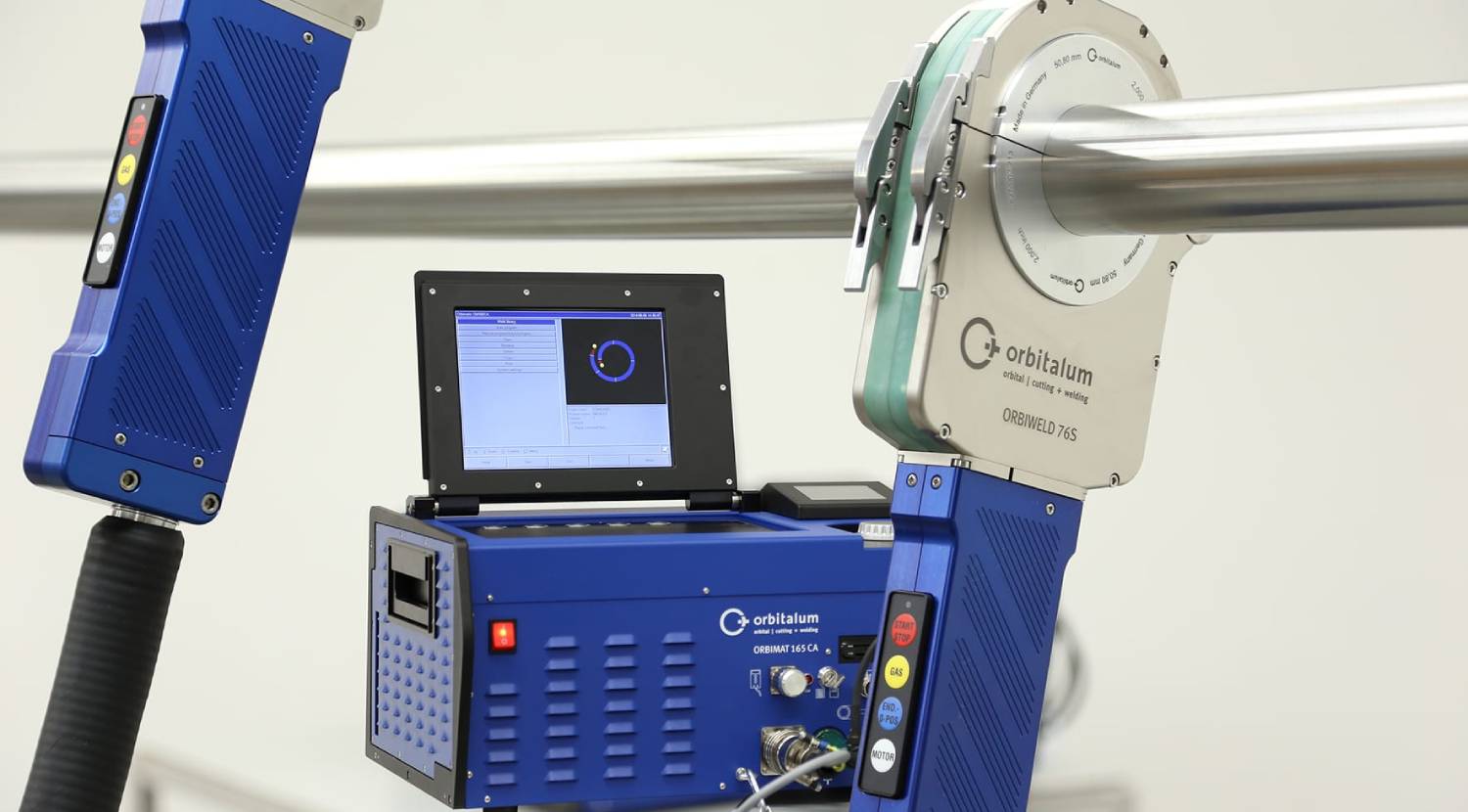

Applications of Orbital Welding

An orbital welding machine is useful in numerous industrial applications. For example, it can be used for joining pipes. While welding pipes by hand can be time-consuming and error-prone, an automated orbital process is more effective. An orbital machine can achieve consistent welds throughout a 360-degree rotation. These advantages make it a viable alternative to manual pipe welding. However, there are some drawbacks to orbital welding.

An orbital welding machine is not appropriate for everyone. The operator needs the appropriate skills and training in order to operate it. However, with proper training and understanding of its mechanics, an orbital machine can be operated by a mechanically inclined worker. This machine also enables faster production and eliminates normal variation and errors. Moreover, an orbital welding machine does not disturb workers. Therefore, if you’re looking for a new job, an orbital welding machine can help you get your hands on it quickly.

Advantages of Orbital Welding over Manual Welding

Orbital welding is a specialized type of welding. Its popularity has increased over recent years, with manufacturing companies increasingly realizing its value. Not only is orbital welding a valuable skill for beginners, but it also benefits experienced welders in a number of other ways. Learn how orbital welding works in this article. And, if you’re still not convinced, read on to learn more about the advantages of this specialized welding method.

An orbital welding machine’s compact design makes it easy to clamp between rows of heat exchanger tubes. A manual welder would have a difficult time getting a repeatable weld. The pharmaceutical industry demands complete penetration of weld joints. Because bacteria and fluids can accumulate in cracks and pits, the weld must be sterile to avoid contamination. With orbital welding, you can ensure complete weld coverage without any overheating.

In Conclusion

When purchasing an orbital welding machine, you should consider the cost of the initial investment as well as the cost of maintenance and repair. A good hardware tools supplier can offer you high-quality equipment and an extensive training program. The initial investment may be high, but it’s more than worth the money in the long run. The benefits of an orbital welding machine are numerous. First, it helps you save time and effort. Second, it makes the welding process more accurate, and it also reduces the risk of mistakes.

“Stop chasing the money and start chasing the passion.”

— Tony Hsieh